Understanding The Craft: A Comprehensive Guide To Backer Rod Manufacturing

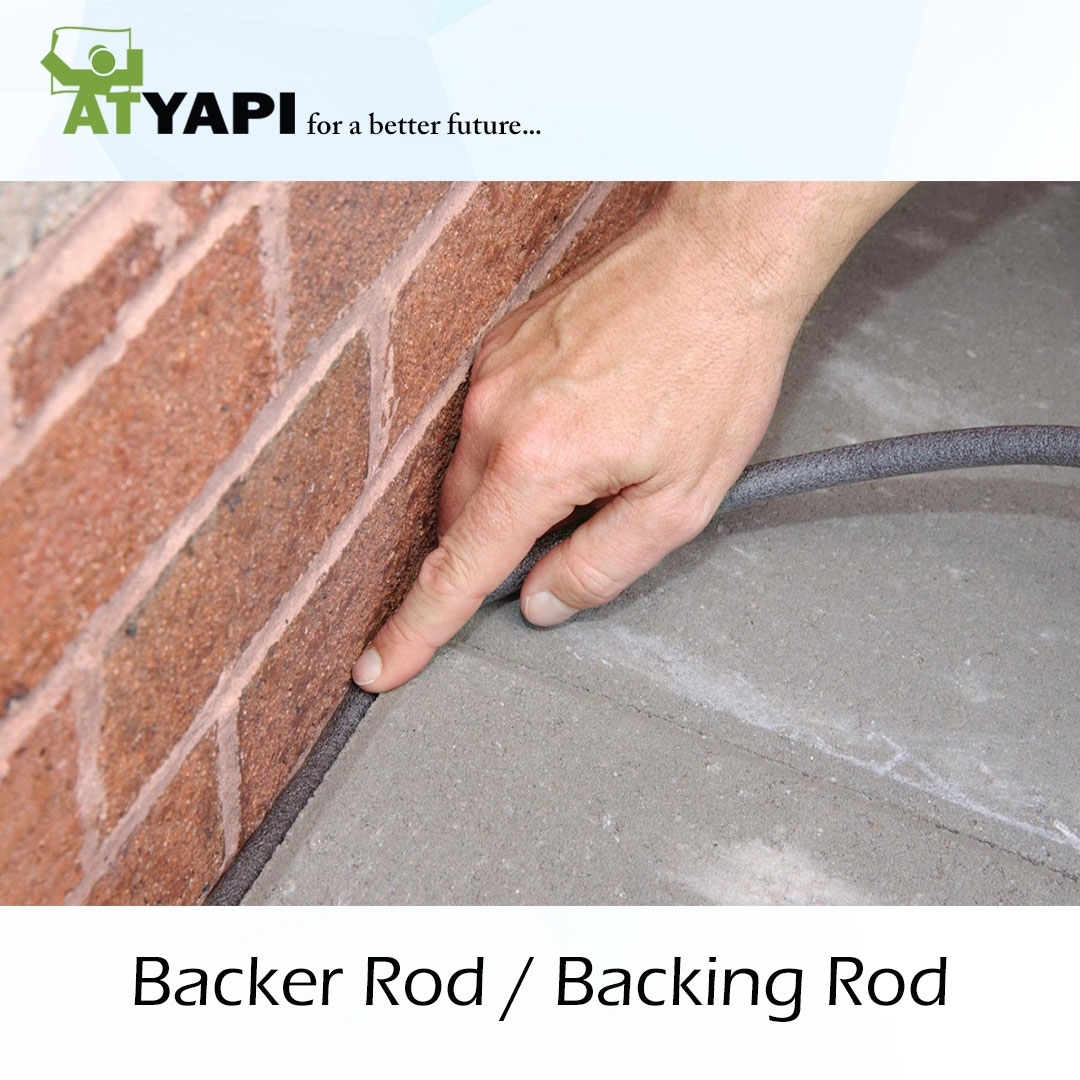

Backer rod manufacturing plays a vital role in the construction industry, providing essential components for sealing joints and gaps. These flexible, foam rods act as a filler material that enhances the effectiveness of sealants, ensuring long-lasting and durable installations. As demand for quality construction materials continues to rise, understanding the intricacies of backer rod manufacturing becomes increasingly important for professionals and enthusiasts alike. This guide will delve into the nuances of the manufacturing process, offering valuable insights into its significance, challenges, and advancements in the field.

In the world of construction, backer rods are indispensable tools that ensure proper sealant application. These rods are designed to maintain consistent joint widths, preventing excessive use of sealant materials while ensuring optimal performance. By exploring the manufacturing process, we uncover how these rods are crafted to meet industry standards and deliver reliable results. From raw material selection to final quality checks, every step in the process is meticulously executed to guarantee superior performance.

As the construction sector evolves, so does the demand for innovative solutions in backer rod manufacturing. Manufacturers are constantly pushing boundaries to develop products that cater to diverse applications, from commercial buildings to residential properties. This article will provide a detailed overview of the manufacturing process, highlight key considerations for quality assurance, and address frequently asked questions about backer rod production. Whether you're a seasoned professional or a curious beginner, this guide aims to equip you with the knowledge needed to appreciate the intricacies of backer rod manufacturing.

Read also:Janford And Son A Legacy Of Craftsmanship And Innovation

What Are the Key Steps in Backer Rod Manufacturing?

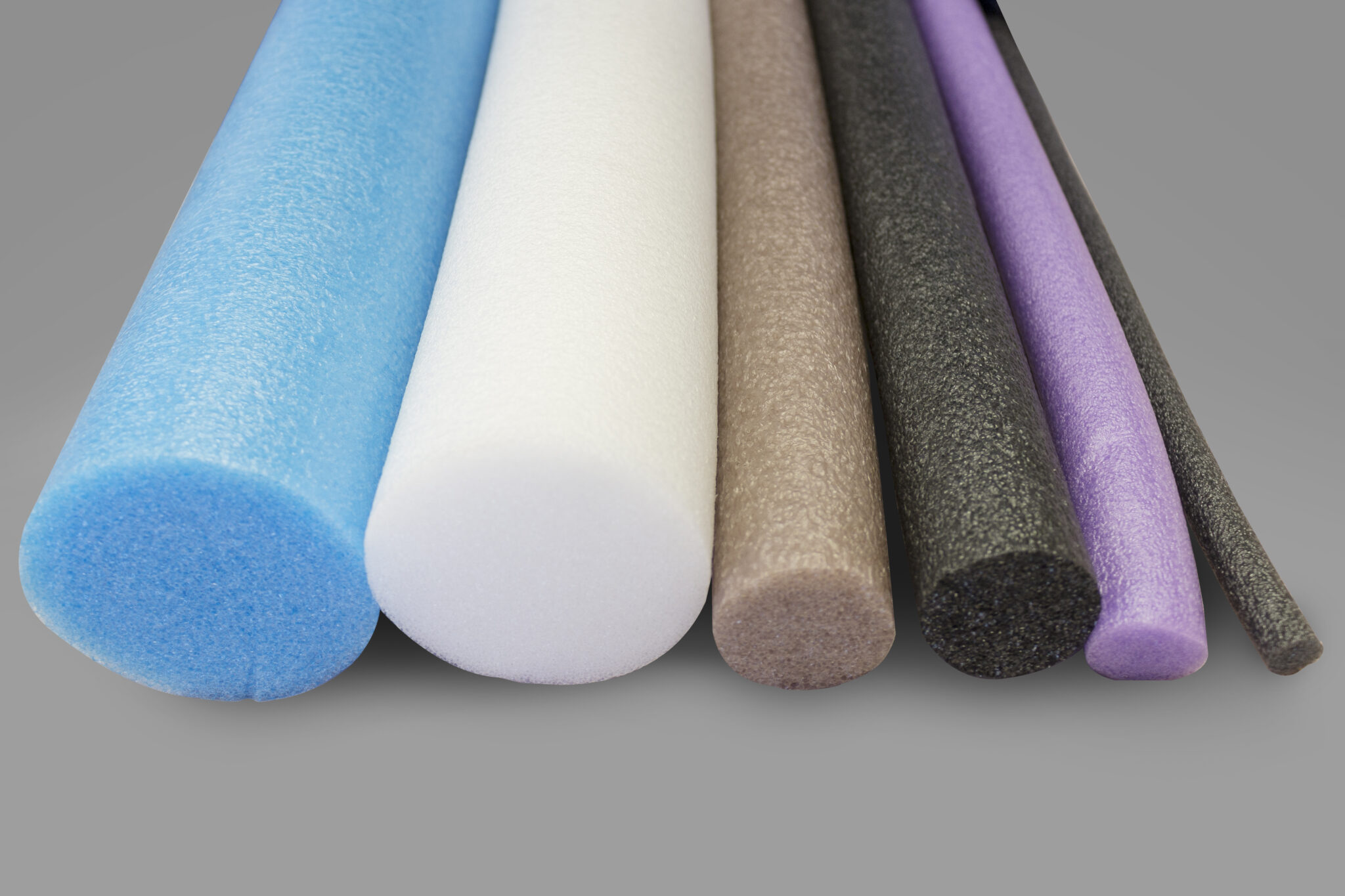

Backer rod manufacturing involves a series of well-defined steps that ensure the production of high-quality rods tailored for specific applications. The process begins with the selection of raw materials, typically closed-cell polyethylene foam, which provides the necessary flexibility and compressibility. These materials are carefully chosen based on their compatibility with sealants and their ability to withstand environmental conditions.

Once the raw materials are selected, they undergo an extrusion process where the foam is shaped into long, continuous rods. This step is critical, as it determines the final dimensions and consistency of the product. The rods are then cut into desired lengths and undergo quality inspections to ensure they meet industry standards. Additional treatments, such as UV stabilization or fire-retardant coatings, may be applied depending on the intended use of the backer rods.

Why Is Material Selection Crucial in Backer Rod Manufacturing?

The choice of materials in backer rod manufacturing significantly impacts the performance and durability of the final product. Manufacturers prioritize materials that offer excellent resistance to moisture, chemicals, and temperature fluctuations. Closed-cell foam is often preferred due to its ability to retain its shape and prevent water absorption, making it ideal for outdoor applications.

Moreover, material selection considers the compatibility of the backer rod with various sealants. Ensuring proper adhesion and cohesion between the rod and sealant is essential for creating a strong, long-lasting bond. By carefully evaluating material properties, manufacturers can produce backer rods that meet the specific requirements of different construction projects.

How Does Quality Assurance Impact Backer Rod Manufacturing?

Quality assurance plays a pivotal role in backer rod manufacturing, ensuring that every product meets the highest standards of performance and reliability. Manufacturers implement rigorous testing protocols to evaluate the physical properties of the rods, including compression, flexibility, and dimensional stability. These tests help identify any defects or inconsistencies that could compromise the effectiveness of the backer rods.

In addition to physical testing, manufacturers conduct chemical analyses to ensure the rods remain stable under various environmental conditions. By adhering to strict quality control measures, manufacturers can guarantee that their products perform consistently across different applications, providing peace of mind to contractors and builders.

Read also:Mike Wazowski 2 Eyes The Fascinating Evolution Of A Pixar Icon

What Are the Challenges Faced in Backer Rod Manufacturing?

Despite advancements in technology and materials, backer rod manufacturing still faces several challenges that can impact product quality and production efficiency. One of the primary challenges is maintaining consistent dimensions throughout the manufacturing process. Variations in rod thickness or diameter can lead to improper sealant application, compromising the integrity of the joint.

Another challenge is ensuring the compatibility of backer rods with a wide range of sealants. As new sealant formulations continue to emerge, manufacturers must adapt their production processes to accommodate these changes. This requires constant innovation and investment in research and development to stay ahead of industry trends.

What Innovations Are Driving the Future of Backer Rod Manufacturing?

The backer rod manufacturing industry is experiencing rapid advancements driven by technological innovations and evolving market demands. Manufacturers are increasingly focusing on developing eco-friendly materials that reduce environmental impact without compromising performance. For example, some companies are exploring the use of biodegradable foams as an alternative to traditional polyethylene.

Additionally, automation and digitalization are transforming the manufacturing process, enhancing precision and efficiency. Advanced machinery and software enable real-time monitoring of production parameters, allowing manufacturers to quickly identify and address any issues that arise. These innovations not only improve product quality but also reduce production costs, benefiting both manufacturers and consumers.

Can Backer Rod Manufacturing Be Customized for Specific Applications?

Absolutely! Backer rod manufacturing offers a high degree of customization to meet the unique requirements of different construction projects. Manufacturers can adjust rod diameters, densities, and surface treatments to optimize performance for specific applications. For instance, rods intended for use in high-traffic areas may require additional reinforcement to withstand heavy loads, while those used in exterior applications may need UV-resistant coatings to prevent degradation from sunlight exposure.

Customization extends beyond physical properties to include packaging and labeling options. Manufacturers can provide rods in various lengths and quantities, making it easier for contractors to manage inventory and streamline installation processes. By offering tailored solutions, manufacturers ensure that their products meet the diverse needs of the construction industry.

What Role Does Sustainability Play in Backer Rod Manufacturing?

Sustainability has become a key consideration in backer rod manufacturing as the construction industry increasingly prioritizes environmentally responsible practices. Manufacturers are exploring ways to reduce waste and minimize the carbon footprint associated with production processes. This includes optimizing material usage, recycling scrap foam, and investing in energy-efficient equipment.

Furthermore, the development of sustainable materials is gaining traction in the industry. Researchers are investigating alternatives to traditional polyethylene foam, such as plant-based bioplastics, which offer comparable performance with reduced environmental impact. By embracing sustainable practices, manufacturers can contribute to a more eco-friendly future while maintaining product quality and performance.

How Does the Backer Rod Manufacturing Process Contribute to Construction Success?

The backer rod manufacturing process plays a crucial role in ensuring the success of construction projects by providing reliable, high-performance materials for joint sealing. Properly installed backer rods help maintain consistent joint widths, preventing excessive sealant usage and reducing material waste. This not only enhances the aesthetic appeal of the finished project but also improves its durability and longevity.

In addition to facilitating effective sealant application, backer rods contribute to the overall structural integrity of buildings. By creating a stable foundation for sealants, they help prevent water infiltration, air leakage, and other common issues that can compromise building performance. As a result, contractors and builders can deliver projects that meet or exceed client expectations, reinforcing trust and credibility in the industry.

What Should Consumers Look for When Choosing Backer Rods?

When selecting backer rods for construction projects, consumers should consider several key factors to ensure optimal performance. First and foremost, it's important to choose rods made from high-quality materials that offer excellent resistance to environmental factors such as moisture, UV radiation, and temperature fluctuations. Additionally, the rod's diameter and density should align with the specific requirements of the application.

Consumers should also verify that the backer rods comply with relevant industry standards and certifications. This ensures that the product has undergone rigorous testing and meets established performance criteria. Finally, consulting with experienced manufacturers or suppliers can provide valuable insights into selecting the right backer rods for specific projects, helping to achieve the desired results.

Conclusion: Embracing the Future of Backer Rod Manufacturing

Backer rod manufacturing represents a critical component of the construction industry, providing essential tools for joint sealing and enhancing building performance. By understanding the manufacturing process, material selection, and quality assurance practices, professionals and enthusiasts alike can appreciate the complexity and importance of this field. As the industry continues to evolve, embracing innovation, sustainability, and customization will be key to meeting the ever-changing demands of the construction sector.

Whether you're a contractor, builder, or DIY enthusiast, the knowledge gained from this guide can empower you to make informed decisions when selecting backer rods for your projects. By choosing high-quality products from reputable manufacturers, you can ensure successful outcomes and contribute to the advancement of the construction industry as a whole.

Table of Contents

- Understanding the Craft: A Comprehensive Guide to Backer Rod Manufacturing

- What Are the Key Steps in Backer Rod Manufacturing?

- Why Is Material Selection Crucial in Backer Rod Manufacturing?

- How Does Quality Assurance Impact Backer Rod Manufacturing?

- What Are the Challenges Faced in Backer Rod Manufacturing?

- What Innovations Are Driving the Future of Backer Rod Manufacturing?

- Can Backer Rod Manufacturing Be Customized for Specific Applications?

- What Role Does Sustainability Play in Backer Rod Manufacturing?

- How Does the Backer Rod Manufacturing Process Contribute to Construction Success?

- What Should Consumers Look for When Choosing Backer Rods?